Sunday, September 29, 2013

Building the finish

After two sessions of padding shellac (and brushing around the peghead). There are only a couple more to go.

Saturday, September 28, 2013

Pore filling

More like "gouges left from ripping tape off of delicate veneer" filling. The Koa parts have actual pores, though. Thankfully the neck is level and does not need this.

Here is the state after a seal coat of shellac on top of the boiled linseed oil; one coat of epoxy smeared into the--uh--low spots, dried, and scraped and sanded back; and a second coat of epoxy applied. Not shown: my feet covered in epoxy shavings after scraping the first coat. It's such a shame to see that wet shine knocked down, but it has to be done!

Here is the state after a seal coat of shellac on top of the boiled linseed oil; one coat of epoxy smeared into the--uh--low spots, dried, and scraped and sanded back; and a second coat of epoxy applied. Not shown: my feet covered in epoxy shavings after scraping the first coat. It's such a shame to see that wet shine knocked down, but it has to be done!

Thursday, September 26, 2013

Finishing

Things are heating up. After taping off the fretboard and sanding for an inordinate length of time, I got a coat of oil wiped on to darken and blend the color.

Sunday, September 22, 2013

Leveling and dressing the frets

I probably could have let this go, but to make absolutely sure the frets were in top notch condition, it was time to level and dress the frets. First, creating flats with one file and removing scratches with the same file riding sandpaper:

The angled files were used to deepen the bevel on the fret ends.

After restoring roundness using another file and more sandpaper:

Tools for dressing the fret ends and sanding the board and frets (not the crayons):

It's looking pretty good to me. Final sanding and finishing are all that's left!

Wednesday, September 11, 2013

Side dots

I got these little guys drilled, installed, and leveled last week. They help a lot, I can attest after nine months without. By the way, it starts with a 1/16" black plastic rod. I also refined and polished the string nut before restringing to make some nice backyard jams with Nick. Two more tasks punched out! I can taste it now.

Wednesday, September 4, 2013

Progress update

My todo list is dwindling as shop time of late resulted in the completion of several tweaks, repairs, and steps to prepare for finishing.

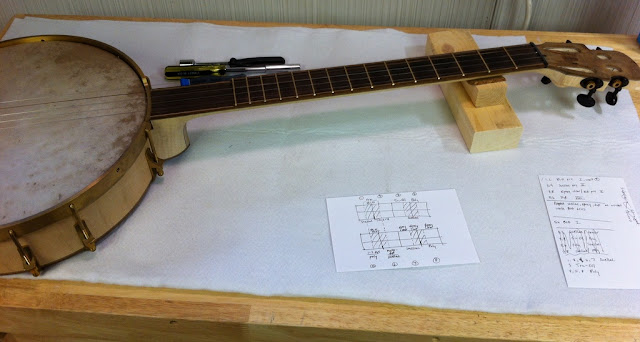

Back on the bench, ready for all kinds of surgery (and a replacement tooth):

Clamped to the neck carving rail (complete with its now solid base) for a bit of wood removal and shaping.

A couple weeks ago I had my proudest builder moment other than the first notes when hours of calculating and working on the heel cut jig resulted in a perfectly aligned neck and perfect string action in one shot. Fists were pumped. Shouts of exhilaration were (m)uttered. As it happened, I took a conservative first cut, thinking I'd double check my thinking and setup before trying to take it all the way, but a mistake in the setup took it all the way unexpectedly and it came out great. When does anything work out that way?! The result was a better looking and more playable instrument. Check and check.

Finish tests continue in order to figure out how to blend the color of the neck and rim and to decide what pore filler and finish I want to use. After tonight there are only two more tasks standing ahead of finish application! Installing side dot position markers and leveling and polishing the frets.

Here is a fun little tool I made tonight to move the peghead through-holes.

None of the three remaining through-holes allowed a straight string path from the nut to the tuner post without rubbing a little. This needed correcting just in case it was hindering tuning at all. I started filing with the needle files, but that wasn't getting me anywhere. I needed a tiny chisel or gouge if I was ever going to finish. I rooted around in the tools to no avail. It was time to sacrifice a 75-cent file. First I bent the handle for a better angle. Then out came the Dremel with a cut-off wheel to remove the tapered end. After a little grinding on the disc sander and mild sandpaper sharpening, it was good to go. It worked. What would you call that, a mini bent-handle plow chisel?

Back on the bench, ready for all kinds of surgery (and a replacement tooth):

Clamped to the neck carving rail (complete with its now solid base) for a bit of wood removal and shaping.

A couple weeks ago I had my proudest builder moment other than the first notes when hours of calculating and working on the heel cut jig resulted in a perfectly aligned neck and perfect string action in one shot. Fists were pumped. Shouts of exhilaration were (m)uttered. As it happened, I took a conservative first cut, thinking I'd double check my thinking and setup before trying to take it all the way, but a mistake in the setup took it all the way unexpectedly and it came out great. When does anything work out that way?! The result was a better looking and more playable instrument. Check and check.

Finish tests continue in order to figure out how to blend the color of the neck and rim and to decide what pore filler and finish I want to use. After tonight there are only two more tasks standing ahead of finish application! Installing side dot position markers and leveling and polishing the frets.

Here is a fun little tool I made tonight to move the peghead through-holes.

None of the three remaining through-holes allowed a straight string path from the nut to the tuner post without rubbing a little. This needed correcting just in case it was hindering tuning at all. I started filing with the needle files, but that wasn't getting me anywhere. I needed a tiny chisel or gouge if I was ever going to finish. I rooted around in the tools to no avail. It was time to sacrifice a 75-cent file. First I bent the handle for a better angle. Then out came the Dremel with a cut-off wheel to remove the tapered end. After a little grinding on the disc sander and mild sandpaper sharpening, it was good to go. It worked. What would you call that, a mini bent-handle plow chisel?

Subscribe to:

Posts (Atom)